ERW Tubing Versus DOM Tubing For Motorcylce Frames!

ERW tubing or Electric Resistance Welded tubing is not as strong as DOM tubing or Drawn Over Mandrel tubing. Usually when tube is made, it starts off as a flat sheet and this is rolled up into a tube and welded. DOM tubing is usually made the same way but there is an extra process where this tube is drawn through a die along with a mandrel to control the outer and inner diameters of the tube. This extra process strengthens the steel since it is cold formed by up to 20%. Another type of common tubing is Chrome-Moly also known as Chromium / Molybdenum Steel. This type of steel also uses the same process but has these additional elements within the steel alloy which increase strength even more. Chrome-Moly is usually used in tubing for cars and other applications over 3500 lbs.

Motorcycle Frames and ERW Steel Tubing...

Motorcycle frames are made with both ERW tubing and DOM tubing. For small engines with not a tremendous amount of horse power a 1" x 1/8" mild steel ERW tube should be fine. Modern engines with a lot more horsepower as well as stretched frames require at least 1 1/4" x 1/8" wall thickness at a minimum. Bigger choppers even use 1 3/8" x 1/8" walls. More on the overkill side done for design or aesthetics is 1 1/2" tube with 1/8" wall. All applications under 3500 lbs pretty much can get away with using ERW. Roll cages and dune buggies, car frames are almost always made with DOM tubing.

All three, Chrome-Moly, DOM and ERW tubing weigh about the same but it is important to note that Chrome-Moly is the strongest, followed by DOM and finally ERW being the weakest of the three. You can take advantage of this by replacing a larger diameter tube with a smaller diameter tube of stronger material. For example, you can replace a 1 1/2" ERW tube with a 1 1/8" DOM or Chrome-Moly tube.

The advantage here is that you can reduce your frame weight by making such a change. It is very critical to confirm that it is ok to make this kind of change on your frame. Each frame has a different geometry and different loads that will bend and twist the steel in various ways. Finite Element Analysis (FEA) conducted by a qualified engineer can provide you with correct tube diameters and wall thickness that can be replaced for your specific frame design.

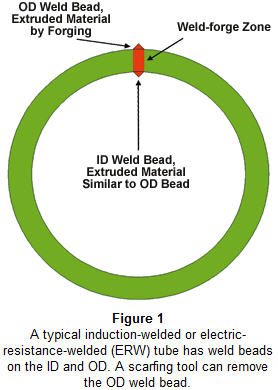

ERW has the weld seam on the inside of the tube (see image above). DOM, although made the same way has the additional process of being drawing and the mandrel removes this seam and provides a nice smooth surface on the inside of the tube.

The image and diagram is courtesy of the fabricator.

New! -- Bobber Frame Plans

Says Daniel Nerf, "I can solve all the issues of DOM versus ERW."

Hi, I'm Daniel Nerf, I am an Engineer here in Dallas Texas.

When you buy your tubing (In the USA) you need to tell them you want ASTM A513 tubing in either DOM or ERW. (Sorry Luke, I do not know the Metric conversion for this Grade, you could ask your local engineer -- in reference to Lukes commentary on our DOM tubing article.)

Both ERW and DOM in this Grade specification has a 50ksi minimum yield rating (50,000 psi). Now, if you want perfectly round dimensional tubing with extremely tight tolerances you buy DOM and pay a premium, or you can buy ERW which has a minute less tolerances than DOM and save a bunch of cash and of course you have to sand the seam.

Both DOM and ERW have a seem, don't kid yourself ! and both can split during bending but not likely.

Also the differences in tolerance between DOM and ERW are so negligible that if you were sand the outside of both tubes you would never know the difference.

Hope this helps, best wishes and keep building. (I know I will !)

Oh, from one of the plans I purchased from you I have redesigned it in to a fully independent suspension Trike frame.

Daniel Nerf

Says, Danny (one of our subscribers):

'Daniel Nerf is not entirely correct referring to DOM vs ERW. And he is leaving out the most important reason you use DOM over ERW; its the yield and tensile strength. ERW does not even report yield and tensile. DOM does report it and it is usually 30-60 percent higher than ERW because it is "cold worked" when it's drawn over the mandrel and through the die. when you cold work steel it increases the physical properties (makes it stronger).'