Motorcycle Frame Jig Blue Prints:

36" x 72"!

Our new motorcycle frame jig blue prints are the only frame jig plans you'll ever need.

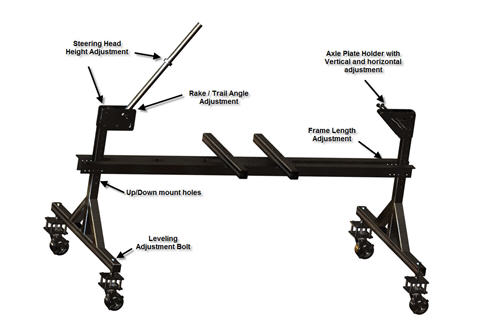

Click The Frame Jig Image To Get A Larger View

The main advantage our plans have over all the other frame jig blueprints on market is that they have multiple sectional views which make these plans easy to follow!

There are many more features and benefits to our motorcycle frame jig blue prints...

Here's 12 Reasons To Get Our Frame Jig Plans:

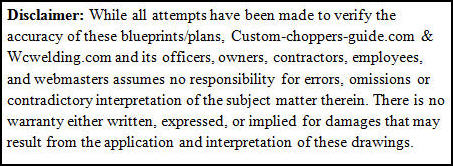

- Wheels allow the frame to easily be moved in your garage in and put away when not working on the frame.

- Wheels have locks and also vertical height threaded adjustment which will allow you to level the jig regardless of how bad the floor is.

- Frame is made with standard 2x2 steel tubing which is very cheap and easily available from various steel suppliers.

- All cuts are easy miter cuts that can be made on a steel cutting band saw.

- Jig has vertical height adjustment which will allow up to 12" of vertical adjustment on the channels. This will make it very customizable so that you can work on the frame at whatever height you feel comfortable with. Whether you prefer to stand and work or sit on a stool and work.

- Rake angle can be adjusted all the way from 0 to 90 degrees. You can also adjust the height to allow the steering head to sit exactly where you need it. The frame jig you'll make from these motorcycle frame jig blue prints will be one of the most useful tools in your shop.

- Rear axle plate holders all have slots which will allow the rear axle plate to be placed exactly where needed in both vertical and horizontal directions.

- You can stretch or shrink the frame up to 8 inches with the holes provided. It is very easy to add additional holes on the L channel and adjust frame length as much as needed. The possibilities are endless. Max frame length is 70 inches.

- Center support channels have 22" of front to back adjustment. This can be adjusted as needed for your application.

- All hardware for adjusting the plates and mounts is identical. All bolts are 3/8" -16 thread and 3" long.

- Assembly is very simple as there are many off the shelf parts such as caster wheels, end caps, hardware, threaded rods, and spacers. Only components to fabricate would be steel mounting plates and cutting the square tubes to size.

- Minimal amount of welding is required. All major components are bolted together to allow for maximum flexibility.

Here's Exactly What You'll Get:

Your motorcycle frame jig blue prints will be printed and delivered 36" x 72" in size. The price for these jig plans is just $49.95 $29.95. Order your set now...

Still Not Convinced? Here's Why You Should Only Buy Motorcycle Frame Jig Blue Prints From Us:

The motorcycle frame jig blue prints were professionally designed with advanced features that will make your frame building project much easier to start and finish...

Our plans were designed by a senior design engineer who went over every single measurement with a fine tooth comb, and then had another senior design engineer proof them.

Our engineer (Mr. Noor) used cutting edge software that would cost you an arm and a leg to purchase, and 20 times that amount to be trained to use it.

As a result what we have motorcycle frame jig plans that are precise, and easy to follow.

Why Our Motorcycle Frame Jig Blue Prints Are The Best On The Planet:

Most plans have a very simplistic view making the angles and measurements difficult to see and understand. But with our new and improved motorcycle frame jig blue prints you will get multiple views which you will not find anywhere else.

Our frame jig plans were simplified by creating special "sectional" views: This shows you how the jig would look if it were cut at a specific plane. And it helps tremendously because the only other way for us to specify those angles (and bends) would be to have multiple horizontal and vertical dimensions on multiple views.

The measurements on these motorcycle frame jig blue prints are as precise and accurate as you will find, and with the multiple views you'll get plans that are the best on the planet, guaranteed. And the end result will be a motorcycle frame jig that your friends will envy. Heck you could go out and sell your completed jigs for top dollar.

Like I said, these plans were not just drawn up on the kitchen table. They were professionally designed, proofed, and then proofed again by a senior engineer.

Click The Frame Jig Image To Get A Larger View

Can the jig be used to build a softail and if so do any adjustments need to be made?

Yes, but we'll need to find a way to lock the frame so that it cannot flex at the soft tail hinge point. Locking the soft tail is necessary for using this frame. When the soft tail hinge is locked, then the frame will behave just like a hard tail and they can use the frame in the same way.

You can utilize this jig to build a soft tail frame as well but you will need to lock the soft tail portion of the frame so that it behaves as a rigid until you are ready to put in the springs/suspension. This can easily by done by aligning the soft tail so that it is in the central location of the travel of the soft tail.

A secondary hold is usually added on the soft tail near the hinge in order to lock the bike into a rigid state. This bolt is usually very small and is only used when servicing / replacing suspension, etc.

The bike should never be ridden with this small bolt in place since it will not withstand the forces and will shear. Once the bolt is in place, the frame will behave like a rigid frame and you should be able to utilize the jig in the same manner. Let us know with questions or concerns.